2016 Update - Part One

During the

2015 Finn Gold Cup it was obvious that the boat and

mast combination was too stiff in the choppy seas and heavy airs. Spoke to plenty of Finn

luminaires regarding just why a soft bow is desirable to maintain speed and height.

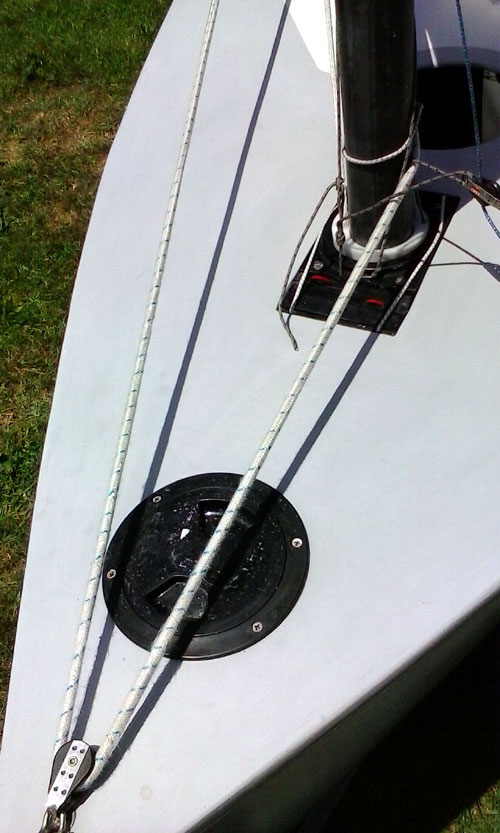

First cut

out the plywood monocoque that supported the mast slide all the way to the bow,

leaving the slot installed in 2015 basically supported only by

the deck stringers running for and aft each side of the

slot plus the 3mm cross ways plywood deck stringers at the back of the mast slide. These 3mm stringers were originally stiffened by vertical plywood backers in a "T" shape, these backers were removed as well.

With the lighter stringers installed in the hull in 2015, the gunnels and the bow sections could now easily be pushed in and were very

flexible. Was going to remove the forward 100mm of the gunnels as on the new Devoti Fantastica's so that they could move independently from each other.

Decided that with the gunnels now having the structural strength off a piece of licorice, to leave them as they were.

New fore deck consisting of a single layer of triple axis fibreglass cloth layed up, glued and glassed on, plus faired. The new deck stiffened up the gunnels somewhat leaving the option to cut the gunnels back, for a later date.

Splashed on a bit of paint and we are ready to go.

First sail immediately proved the softened bow worked as desired. The previous very narrow sweet spot between being powered up and and needing to pinched up to remain flat whilst hiking out, is now much wider. Much easier on the tiller without needing the quick and twitchy rudder movement to keep the boat flat and progressing forward.

Well, that is the first part of the 2016 upgrade finished.

Next we will take out the 6mm plywood floor and replace

it with a 4mm one. When we originally built the boat,

the construction of the join between floor and sidetank was not robust enough.

A crack opened up on the join line, letting water into the 6mm plywood floor and

even though it was sealed with epoxy resin, it rotted away.

After putting a number 10 size hoof through the floor, a replacement was urgently required.

Onto part two where we put in the new lightweight floor.