On The Diet - Part Three

Having achieved a theoretical weight saving of 6.5 kg so far, other areas where weight savings were explored and with the attitude that every little bit helps, it doesn't take long for another kilo or so to disappear.

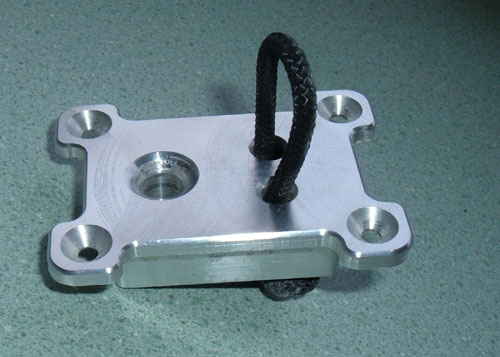

Example being the bow stainless fittings to anchor the boom bungy cord. Replaced with custom alloy fitting that enabled the bungy cord to be adjustable (not required in windy days) plus have a simple rope as the towing eye.

All 10mm diameter control ropes were replaced with 6mm ones. Easy half kilo lost.

When filling and fairing the new light weight decks it would have been very easy to increase weight just to get the super smooth and

furniture grade finish. The Finn is a racing machine not a piece of art, dings and bangs are going to mar the surface with hard

racing so why finish it to the nth degree.

To save weight, time and effort simply left the decks in a

respectable finish

and applied a low sheen paint finish. Bonus is the low sheen will be better on sunny days with its low reflective index.

Coating used was the much revered

Resene Durapox Two Pack Epoxy Coating. Simply rolled two coats on using a small foam roller (wet on tacky) and called it

finished. Used on Americas Cup boats so is good stuff.

Touch dry in 2 hours hard in 24. No need for multiple undercoats

and gloss polyurethane topcoats. Available in any colour. I only used the standard grey and white. Used four parts white to 1 part

grey on the decks and straight grey in the cockpit. Cheaper too at only $60.00 per litre compared with $120 odd for two pot

polyurethane. Repairs are simple.

With the theoretical weight well down below the limit, the damaged areas on the hull were only recoated. Did a bit of a graphic paint job just to be different. Again it was really simple, mask and roll. Sanded the bottom with 400 then 800 grit wet and dry. Now for the weigh in and the swing test to bring her back up to legal.

Places where more weight can be lost

1-....Hull coating system where five coats of polyurethane paint protect and

fairs the fibreglass hull. Easily replaced with two coats of the magic Durapox. Weight saving of about 1kg.

2-....Transom

can be lightened like the decks. There are enough

scantlings built in during the first rebuilt to support the rudder gudgeons.

Possible .5kg weight saving.

3-....Centreboard is full size and weight. Could quite easily cut a holes in the top section

and loose possibly another 1 kg.

Still keen to reduce hull weight further so the old paint work and remaining gelcoat were completely removed and the hull thoroughly

sanded till the weight was down to 105kg including all fittings except the centreboard.

Because the boat was rebuilt with

stringers and bulkheads, it was possible to sand back the laminate without loosing strength in the hull.

Not recommended

unless one is sure of the construction method and laminate layup prior to gelcoat removal.

Laminate was sealed with two

coats of 25% thinned epoxy resin before rolling on 5 coats of the magic

Resene Durapox Two Pack Epoxy Coating wet on tacky. Completely sanded back till the laminate was grinning through the paintwork and finished with wet 800 grit

paper.

Accurate weigh in at the 2010 Finn Nationals on the electronic scales confirmed to total hull weight at 116 kg. The workshop weighing technique using

3 bathroom scales was completely accurate.

Latest 2011 update.